Modern, high-tech products rely on systems engineering to realize designs that fully integrate software, mechanical, electrical, and electronic components. But despite how important they are to the product lifecycle, processes for systems modeling, requirements engineering, simulation-driven design space exploration, and variant management all too often happen outside of traditional enterprise PLM systems.

Aras Innovator is different. To see how, check out the video below, which overviews the third webinar in the recent Digital Thread in Action Aras Virtual series, Systems Thinking and Digital Transformation. Then, read on to learn five reasons to integrate systems engineering with PLM and how Aras does it.

What Is Systems Thinking and Why Do We Need It?

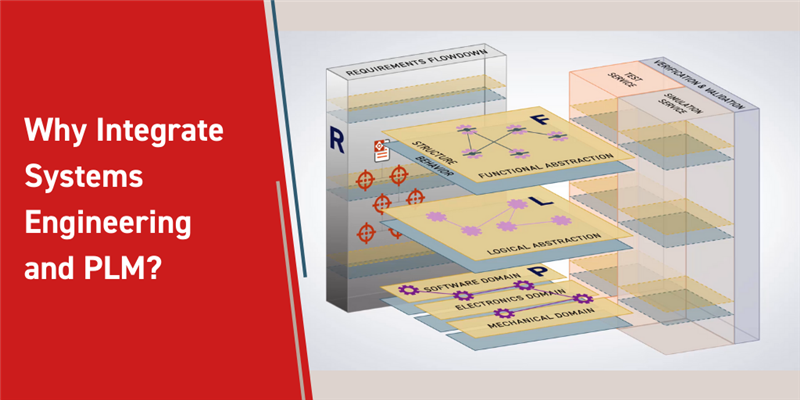

As products grow more complex, more analysis and understanding of their constituent behaviors and interrelated components is necessary, along with how they fit into the context of the larger systems in which they operate: systems including users, other products, the environment, and more. This ability to understand, define, and optimize design intent helps engineers to avoid undesirable emergent properties. It drives requirements development, architectural and behavioral models of the overall system and its underlying subsystems and their interactions, and the implementation of physical components across mechanical, electrical / electronic, and software domains. Finally, it drives verification and validation via physical and virtual methods (or, simulation).

All of these elements are essential to modern product development, from the high-level design abstractions to the simulations that “run” and analyze them, to all the changes that will happen across the system—requirements through physical parts—to get the final design right. This constant, iterative loop is too often performed in separate, siloed systems. Yet teams rely on close cross-functional collaboration to do it. And that’s where PLM comes in.

1 – Integrated Processes for Integrated Systems

Why incorporate systems engineering and PLM? In short, tomorrow’s products rely on it. Products are no longer standalone mechanical systems, or even mechanical and electronic / electrical systems. Modern products increasingly rely on software for functionality, which means the embedded software that drives them needs to be well-integrated with mechanical and e/e components for the entire product to function as expected. Integrating related data from vastly different domains, keeping changes in synch as teams add new information, and ensuring that verification and validation is still sound despite product changes can all be achieved when systems engineering and PLM are closely connected on one platform.

2 – Iterative Design for Continuous Improvements

Building out a system’s expectations, and managing them carefully as they develop and evolve throughout product development, is the role of Requirements Engineering. This process starts early in the concept phase, long before physical parts are designed, to understand, systematically, how the product should function. Then, through Systems Modeling, engineers determine how the product and its subsystems will fulfill these requirements. This is an iterative process, requiring many revisions of systems models, to understand how each part of the system will fulfill its function, as well as frequent revisions to requirements each time the system’s design changes, to ensure requirements are still being met, or to adjust them when they aren’t. With requirements and systems models managed together, these changes can be passed back and forth easily, throughout the product’s evolution from concept through production—and beyond.

3 – Evolving Products to Better Meet Customers’ Needs

Even as products evolve to the detailed design phase where physical parts are incorporated, new realities—the limitations and possibilities introduced by physical parts’ real-world performance—must be incorporated back into system models, and requirements, to verify that requirements are still being met and systems still perform as expected. This iterative process can extend out to the field, as well. In our example above, new customer applications for the product—excessively hot operating conditions—introduced a new requirement to the next-generation design of this product. Connecting even early concept design to the Digital Thread transmits important design parameters to the field, so it is clear what to measure and what constitutes expected performance. And, it connects vital feedback from the field back to the engineers designing next-generation systems, to ensure customer needs are met, better and faster, with every new product to hit the market.

4 – Overcoming Siloed Teams and Tools

When product changes impact so much of a design—systems models, requirements, and even simulations—the many tools required to verify their potential success or failure can make the process of implementing those changes take much longer. Changes typically require teams across multiple disciplines, each using many different tools for the job, along with manual hand-offs of data among teams that add not only time but also the potential for error. Aras Innovator offers a completely open platform that manages data from multiple authoring tools. Engineers continue working in the tools they prefer, and their data is managed and accessible centrally for collaboration and change across multiple teams, enabling better communication and accelerating the change process.

5 – Accelerating Product Development

Design change is the purview of PLM. Integrating typically siloed tools for systems modeling, requirements management, and simulation by managing their data in PLM, in context with other relevant part information, can help notify diverse teams across the organization of the need for change as it arises. They can more quickly and easily locate the latest version of information across each domain, examine interdependencies, and propose a response in a way that brings teams from other disciplines into the process. Teams have visibility into one another’s results, democratizing complex inputs and results, like those for simulation processes, via accessible user experiences that are easy to navigate, understand, and reuse: even for non-subject matter experts. Integrated product development technologies amount to more closely integrated teams, and that means more efficient and more effective product development processes.

Why Aras Innovator?

By managing systems models that incorporate multidisciplinary product considerations—functional, logical, and physical (including software)—on one platform with the requirements that drive them, the simulations that validate them, and the physical parts that fulfill them, Aras Innovator enables a tightly integrated loop of design. It allows for changes not just in a linear fashion but an iterative one, because when one part of the product needs to change—a physical part, say—then the ramifications of that change throughout the system can easily be considered by tracing along the Digital Thread to each part of the design that change will impact.

To see how the Digital Twin is part of the Digital Thread in Aras Innovator, check out this video overview. And to see how the Digital Thread is central to effective change management, see the second video in this series.