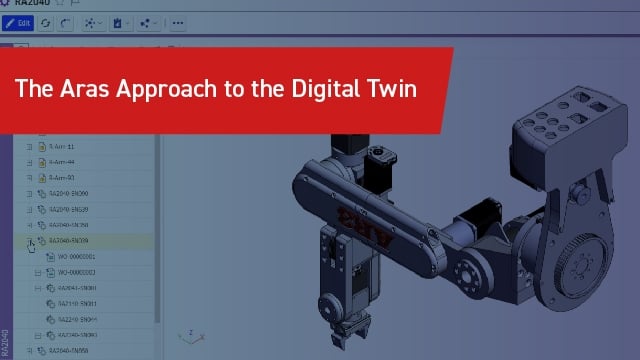

What is a Digital Twin? Everyone you ask might have a different answer; but, in Aras Innovator, our viewpoint is distinct, and you can learn about it right here. If you missed The Digital Thread in Action webinar series last week, check out the replay of first session, The Digital Twin in Maintenance and Service, to see the Aras approach to the Digital Twin and to learn what sets it apart in the market.

Or, watch the quick video below for an overview, and read on to check out five ways a Digital Twin in Aras Innovator is different…

Five Ways a Digital Twin in Aras Innovator Is Different:

1 - The Digital Twin Doesn’t Stop at CAD.

For Aras, the Digital Twin does not stop at CAD. CAD is only the beginning. Visualizing the digital design for a physical asset in the field is useful; but viewing rich engineering, maintenance, and operational data in context with the actual physical configuration of parts onboard the product in the field helps to better guide the work of maintenance and engineering teams alike, so they can improve the product more quickly and efficiently. With Aras, these teams can leverage multiple views of Digital Twin information side-by-side, like serialized part history when service and maintenance leads to component replacements, along with data from engineering, like problem reports and service bulletins.

2 - There Is One Digital Twin for Every Physical Asset.

If companies want strategic visibility across all assets, a simple “pilot project” that creates a single digital twin for a single asset will not cut it. Digital Twins at scale mean one digital twin per asset in the field, which means they must be straightforward to manage and view either together or alone. That's exactly what Aras delivers. To see how a Digital Twin is built, and to see one with a thousand parts, not just a few dozen, register for the May 14th Demo Series: Digital Twin: How to Build, Manage, and Enable a Powerful User Experience

3 - The Digital Twin Captures Every Change in the Field.

In the same way engineering parts evolve from concept, to development, to manufacture, those same parts do not stop changing once they become physical, serialized assets in the field. Quite the contrary. Every time maintenance replaces a part, that change is captured in the Digital Twin in Aras – becoming part of its unique history. This record of changes is key to understanding metrics like mean time between failures and mean time to repair, while broad visibility across Digital Twins and their performance data can greatly accelerate root cause analysis, corrective action processes, and engineering changes to resolve performance issues and improve product quality.

4 - The Digital Twin Is Part of the Digital Thread.

Where can you go from the Digital Twin? In Aras Innovator, the Digital Twin is connected to its entire Digital Thread of information across the PLM system, including engineering parts, work orders, quality data, service information, manufacturing process plans, technical documentation, and more. As part of the Aras platform, a Digital Twin becomes another, extremely valuable view into your product’s complete lifecycle that you can navigate to from other data across that lifecycle. And, in turn, you can navigate from the Digital Twin back into related engineering data on the Aras platform: quickly, easily, and efficiently.

5 - The Digital Twin Connects Performance and Design.

A Digital Twin should not end with performance information. While this information is key to understanding and maintaining assets in the field, it lacks meaning—and the ability to improve next-generation designs—without context from engineering data upstream. These essential connections from upstream design all the way through to downstream performance, available only on the Aras platform, help teams like Quality identify the root cause of issues faster, to reach the right resolution. Engineering can leverage simulations, run using real-world operating information, to evaluate the impact of unexpected conditions on their designs and introduce fixes sooner. And Service teams can quickly communicate with and explore data from teams across engineering, quality, and simulation to improve the work they do.

See how engineering leverages visibility into Digital Twin data in the next blog in this series, which will overview the second webinar from the Digital Thread in Action series: Engineering Change in a Connected World.