Everyone who has seen the movie A Few Good Men remembers the courtroom scene with Jack Nicholson weaving his craft. The idea that the truth is hard to swallow translates surprisingly well into the world of product development and product lifecycle management.

No longer is PLM just about data and CAD management; it even extends beyond the boundaries of an innovation platform. -Kirk Carlsen

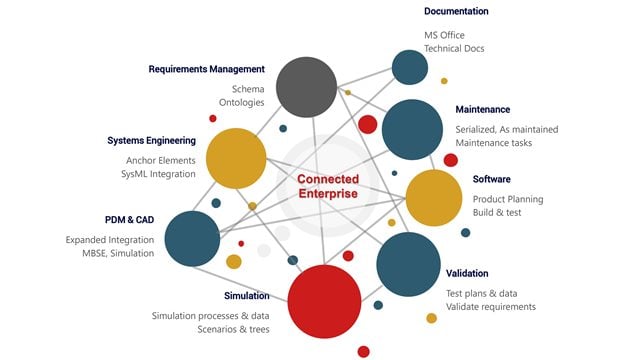

Product Lifecycle Management has grown and morphed over time from simplistic CAD data management into a multi-domain, connected platform. The lifecycle of PLM software (see how I did that?) has seen a consistent increase in incorporating both additional domains and their tools – for example Systems Engineering. Interestingly, those domains have been considered part of the academic definition of PLM for years, however, the “big box” PLM systems have only recently started bringing them into the PLM fold – you should ask yourself why.

All of this increase in capability in PLM is intended to create an integrated environment where all of the data related to the product and process are stored. We should know when problems in the field drive a Problem Report that in turn drives an Engineering Change AND who signed off on them. We should be able to see what system model elements, simulation, and validation test are driven by a given requirement.

Bringing all of the data together and providing linkage and traceability is what we call the Digital Thread. The theory also goes that this increase in capability should also establish the Single Source of Truth. This is where the harsh reality starts to set in.

Truth #1: Single Source of Truth ≠ Single Vault of Truth.

Lionel Grealou, a digital transformation evangelist, writing about Single Source of Truth noted: “SSoT is often mistaken for a single database or repository for all data; rather it implies an intelligent enterprise data model constructed for optimum data integration and control across multiple sources, avoiding duplication and redundancy.”

Lionel is spot on. Creating a single source of truth does not mean that all of that data needs to be in one place. It means that there is only a single master of the data in question. That data may be used in many other projects, departments, and even in different software tools – but only by linking to that master. This is the idea behind the Single Source.

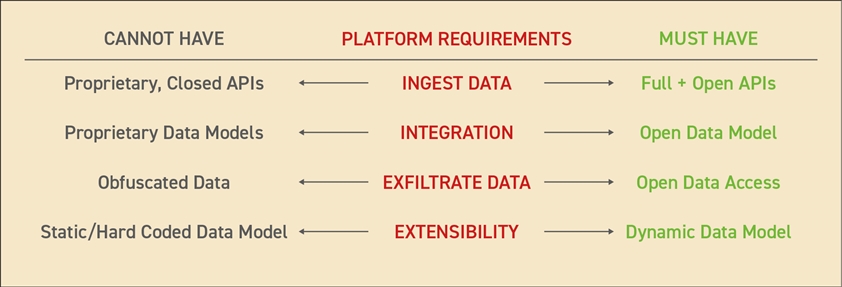

Additionally, not all Product Data Management systems and authoring tools fit well together. That is okay as long as the Single Source concept is retained. Put simply you can not shoehorn a data model from a modern authoring application in to a 30-year-old PDM data model. The idea that you can is myopic.

Truth #2: Domains will always use their favorite tool

Pick a domain…any domain and ask them about their tool of choice. What you will see is that each domain has their favorite. That is fine. People use what they like. But often the choice of tool is not from the same vendor as their PDM. More often than not that is because a company that is focused on a singular area will be good at it. Some examples:

- MBSE – Dassault Cameo

- Software Development – Microsoft Visual Studio

- Simulation – Ansys

- Agile Project Management – Atlassian Jira

The common thread in all of these favorites is that not one of them comes from a company that makes PLM. The real trick is ensuring that the various datasets that are generated can be configuration managed, revised, related to other items. More often than not, they live in disconnected silos relying on Excel and email to share data.

Truth #3 – Silos exist

Enough said. They need to go!

Truth #4: Things change

It seems like every time I go to a conference, I see a group of recent college graduates that have created the next great tool. And you know what? That is a good thing. It keeps the wheels of competition going. We have seen this in the CAD wars over the past 20 years. I used to be a NX guy (yep, my competition in PLM – but Aras does not make CAD tools). Other CAD vendors need to keep inventing to stay ahead of their competition like Catia and the upstart, OnShape.

As those new tools appear, firms say “Hey this might be better than tool X. Let’s give it a try.” Normally a department or program will take the lead on adopting this new tool into their processes. After a while they really like it. Guess what? See Truth #3.

These truths have made it near impossible for firms to successfully transform their businesses – because their Legacy PDM can’t handle the truth. It is holding them back. Still passing requirements from your Requirements Management tool to your design and validation teams via Excel? Can’t handle the truth. Do you have multiple tools in place because the “old school” users still like the old one and the new guys like the new one? Can’t handle the truth.

Time For a New Lens

All these truths do not mean that the vision for PLM 4.0 and beyond is unachievable. It means that firms need to re-evaluate their PLM roadmap and look at things through a different lens. Product Lifecycle Management, as the name suggests, is “all about the product.” It is not a CAD tool or software IDE . It is a business process.

Since PLM is a business process, methodologies form the foundation of product development. Methodologies include how to model a system architecture, how to best simulate a use case, how to test the use case, etc. But most important methodologies also determine the relationships between the items I noted AND what data they share. While Legacy PDM is focused on managing CAD data the processes are left by the wayside. This is where a PLM platform comes in. A PLM platform is created to deliver a connected enterprise with all of these truths in mind.

By taking a platform approach, a firm has options and can control its own destiny. A platform can connect disparate people, processes, and tools into an integrated environment. There is no need to throw everything away and start fresh. You have product to deliver and that takes too much time! So, here are a few things to help you along your journey.

Focus on methodology. Understand your business processes and focus on how things get done. Understand what data is important to other users in the enterprise and how to link/federate to important data (to achieve a Single Source of Truth). Also determine data governance and access control as well. Most important - don’t let your PLM system dictate your process. PLM is intended to implement and automate YOUR process. If it can’t – it’s time for a change.

Use best in class tools or those that best fit your firm’s needs AND integrate them. Your needs are going to grow. As that happens—change tools. The universal constant needs to be the integration – no more silos! From Word to NoMagic to Ansys. Connect those tools so they get out of the silo and the data is managed. This becomes very powerful when important inputs are passed into a model from the platform. A great example is a maximum load or stress that can be stored as a requirement and passed into the simulation tool for virtual analysis and the test plans to validate the simulation.

The same applies to your legacy PDM. The PDM that manages your CAD likely works fine.There is no need to replace it and forfeit your investment. Integrate it to a PLM platform that can support passing data back and forth, manage access control, and configuration management. We are still maintaining the Single Source of Truth in this model (ask General Motors). We have thrown out the fallacy that everything needs to be in a single vault.

“It is not possible to establish single data source and store all data in a single database. It is too limited and it doesn’t scale from all standpoints.” - Oleg Shilovitsky

This concept can be grown to apply to other TDM/PDM systems you may have. The PLM platform will connect to the individual PDM vaults and become the reference to use the data in other processes that need it. This delivers not only the Single Source of Truth but the Digital Thread as well.

Finally, if your business processes are not changing – you are not getting better. If your Legacy PDM system is not helping you to enable the new processes, it’s time for a change. Resilience is a key facet of the ability of a PLM platform to support your firm’s growth path.

The Aras platform was specifically created to support these use cases. This is accomplished with the requirements that we applied to ourselves. When you are ready to take a look at a new way to support your businesses needs, watch a few of our videos to get a feel for what we are all about and download Aras Innovator and give it a try for yourself. When you are ready, let’s build a proof of concept so you can see it for yourself with your own data.