Much hype has been generated around the concept of a “Digital Thread” for product and services companies. As with many buzzwords, the thought has crossed my mind more than once: can it be made real?

To find out, watch the Digital Thread in Action series: a three-part webinar event demonstrating how a digital thread can be realized in PLM to improve service, engineering change, and next-generation design.

For a quick preview of the series, check out this video below:

A Thread by Any Other Name

My 11-year career in PLM began in quality management and reliability engineering software, where the only feedback I heard more often than, “We have more acronyms than any other industry,” was, “We called this something else before.”

And maybe “Digital Thread” is just another name for a very familiar concept in product development: the ideal ability to see into, understand, and trace every possible configuration of a product as it evolves throughout development, manufacturing, maintenance, and operation. It’s called Product Lifecycle Management, after all, but, for most OEMs, that management ends when products roll off the production line. If we knew what happens next, and why it happened, how much faster and more effectively could we improve product quality and customer experience?

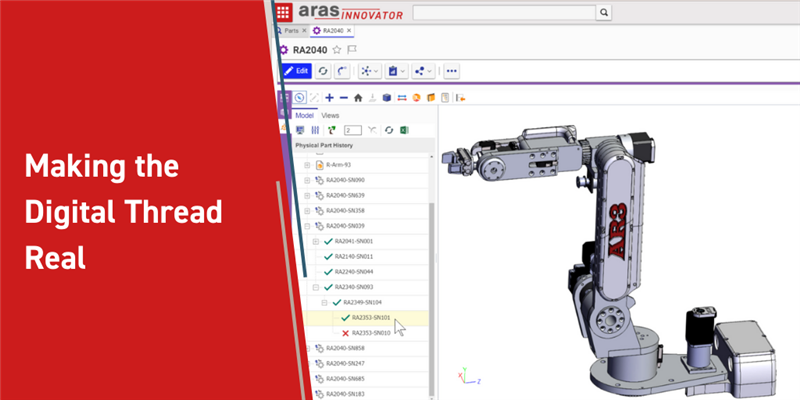

So, how do you make it real? For Aras, the digital thread includes information about the product in the field—known as the Digital Twin—which we define as the current configuration of an individual instance of the product: the one that just happens to be in operation now. It will likely have undergone service operations and the replacement of serialized parts; both types of events which are, in turn, captured in the digital thread to become part of the product’s traceable history.

This means that, for Aras, the digital thread includes as-serviced configurations of the product. It connects data about every product configuration through as-built to as-maintained and beyond—including all of its service experiences, serialized parts, and performance data—together with design-phase information, on a single platform. You can visualize and navigate to any type of related data in any direction in order to create and discover relationships, gaining insights to improve your products faster and more effectively.

And, spoiler-alert: it’s a game-changer for product quality.

Alas, Poor Software

Modern products rely heavily on software to drive functionality, improve user experience, and provide nearly instant, over-the-air-updates that no hardware upgrade can hope to match for speed and convenience. But software is typically developed using different processes and systems than those used when developing mechanical and electrical parts: processes and systems that, traditionally, have little or no integrations with traditional PLM.

But with an increasing reliance on software comes an increasing need to coordinate hardware and software configurations. Software versions need access to data about which versions of hardware configurations they work with, to ensure they match upon installation, and each hardware version needs a reliable trace to the software configuration it has onboard, in case any of its performance issues (or successes) are traceable to its non-mechanical components.

So, how do you make it real? Managing Digital Items in Aras Innovator enables coordination between software and hardware components in a system—and that means change management. Manage links to content in external systems where software is developed, and include software items in engineering change orders. Create relationships and dependencies among different software items managed in Aras Innovator that will be impacted when changes happen, ensuring traceability and accountability to keep every vital component in your product—hardware and software—in sync.

Et tu, Systems Engineering?

Just like software, systems engineering and simulation also find themselves vitally important to modern product development, but similarly disconnected from hardware design processes in traditional PLM. Separate systems, specialized tools, and results that are sometimes only accessible to experts in a narrow field all slow the progress of engineering changes, be they product improvements or new features in development.

But the importance of systems engineering and simulation to developing complex products cannot be overstated. Product development leverages them during digital design to discover and correct potential issues before they become problems in physical products. Analyses can be re-run using real-world inputs in place of expected conditions to help companies better pinpoint customer issues and improve products faster. And, in the early concept design phase, engineers analyze and explore possible approaches to system design, using these tools to develop requirements and—ultimately—the physical parts that will fulfill them.

So how do you make it real? I’ll have to refer you to the webinar series for this one. For me personally, the best part about supporting this demo development effort was seeing my personal vision for PLM over the last 11 years come to life. The ability to click through from requirements, to the system elements that drive them, to the simulations that validate them, to the physical parts that fulfill them—all in one seamless user experience—embodies the digital thread itself: complete traceability from one element to the next, including change management that carries new design decisions through to downstream manufacturing, technical documentation, and service information.

To Platform or Not to Platform?

How did Aras make it real? Uniquely, both the platform technology and the business have been steadfastly committed to openness and interoperability, so users can choose from a wide range of software commonly used to author systems models, simulations, software items, and other enterprise data, including other PLM systems. Artifacts from these commercially available systems can be managed in Aras Innovator the same way as data authored natively on the platform, creating and maintaining a seamless digital thread as data moves through change, collaboration, and other PLM processes.

What’s more, Aras has been uniquely committed to rewriting any software it acquires as a company onto the platform as a native application, rather than standing it up alongside PLM with new branding and/or a few, limited integrations. To see the full impact of these business and technology decisions, check out the Aras Virtual webinar series and see how two recent software acquisitions, in Maintenance Management and Simulation Management, have been brought into the digital thread in Aras. These interact seamlessly with new and forthcoming applications you’ll also see—for requirements management, systems architecture, and variability management—as well as with traditional applications for product engineering, manufacturing process planning, and quality management.

Now that I think of it, I’ve changed my mind. After 11 years in the industry, finally seeing closed-loop quality come to life in a vibrant Digital Thread that connects product performance data with responsive engineering change, governed by compliant quality processes—has been my favorite part of this project.