Is your company CAD-centric? CAD-centric means your focus is on model-based 3D representations of a product. The revision of a part will be the same as the CAD version. Often this practice has been driven using file-based storage in Windows Explorer, where it is easier to search for inadequate functionality in an existing PDM system.

Comments like "the drawing and the model are both used together to represent the same product, their revisions should track together" are fundamentally incorrect statements for an engineering company.

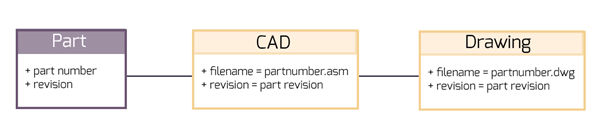

Here is the typical scenario for linking the revision and name across different item types for mechanical designs:

Operating in this fashion presents two distinct risks:

1. You must revise all 3 objects if you modify 1.

An example: A wrong date, a dimension missing from the drawing, or missing associated text on a drawing will drive a revision change. If you need to revise the drawing, the consequence will be that the 3D model will need a new revision to match. And now your ERP part needs a new revision as well.

The downstream impact…for manufacturing, consider what drawings exist on the shop floor. What drawings are with your suppliers? For the supply chain, consider the stock on order or stock manufactured. Should it be scrapped? Can it be used as-is?

This scenario can cause a chain of consequences downstream that results in a mess for the rest of the organization.

2. You lose track of changes.

An example: Updating a drawing without changing the revision number. You may recognize the scenario... "It is only adding a small amount of text, so we don't need to worry about the 3D model, and we don't need to worry about ERP." So an exception is made to open the drawing to make the change and keep everything else the same. (Shhhh, no one will know!)

The downstream impact…may not be immediately known. For manufacturing, what drawings exist on the shop floor? What drawings are with your suppliers? Can you really ensure that your engineering team knows exactly where a drawing exists downstream in the business, and who saw that drawing in its original format? The impact in the design office may also be unknown. Consider what will happen if the next revision is currently being worked on in 3D. Now, you need to be careful that someone does not press refresh on the drawing and update the dimensions when the intention was only to update the text. Imagine you get audited – you will fail if even one of these old drawings is found on shop floor and doesn't match the official released drawing.

In conclusion, you could have two physical drawings that have the same name but different content.

Explore your possibilities with BOM-centric thinking!

Being BOM-centric-driven is a different mindset, putting your product configuration front and center for your business. It is appreciating that you have connected data and documents, and that all of this data will evolve organically over time. Sometimes the changes impact other items and sometimes they do not. By focusing on the product as a whole and not solely on the CAD version, you can associate more data with your bill of materials and have more trust that the connection between objects is accurate.

What if I told you that there is a tool that allows you to do this….. A product lifecycle management (PLM) system!

One of the primary benefits of a PLM system is configuration management. This means you keep all objects in sync without worrying about naming conventions and complex business protocol. Information flows in a different way, metadata on objects can be passed where it is consumed and where it is needed.

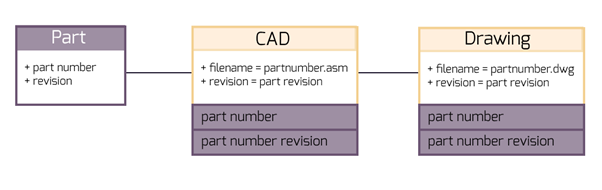

In this diagram, the same objects are referenced but now metadata is captured rather than a hard link to a part or drawing. This allows a distinct revision sequence for the drawing, and for the part.

There can be independent changes on the drawing while keeping the part revision stable; the drawing revision will progress to versions 2 or 3 or 4, and the part revision stays at A. This provides better quality drawings without actually cycling the part definition.

Are you having similar problems in your design office? Are you sick of engineering changes? Would you like to be able to search for drawings on more properties than the filename? If the answer to any of these is yes, then please get in touch.

For more information on the benefits of using your multi-CAD and PDM tools with Aras, watch our on-demand webinar.