For companies that have tried and failed to create sustainable connections to information critical for use cases for product development, closed loop quality, or maintenance effectiveness, don’t give up, help is on the way. We have seen the “Bat Signal” and are coming to the rescue, for we have four superpowers, contained in our platform, Aras Innovator, that will make the difference in the future of your product lifecycle.

Companies need to share critical information contained in siloed applications or tools with others in the organization. This allows them to deliver complex, high quality products at scale. Only a platform can make and sustain connections to critical applications, creating the ability to manage information related to a product across the product lifecycle with context.

Doing this correctly creates the ultimate superpower, the digital thread. This superpower provides the ability to trace a product’s digital history and all its related digital assets across its lifecycle. From the initial planning and analysis, through design, manufacturing, and testing, and then on to field operation and disposal, the digital thread weaves together the meaningful relationships, connections, and decisions that drive bill of materials, parts, software versions, electronics, CAD models, documents, production plans, and service records.

But to get there you need a platform, with four key superpowers, to transform your product lifecycle, ensuring it is sustainable, no matter what villain comes your way.

Ability 1: Break any Lock: Connect, Federate all Product Data

To attain digital thread, data needs to be accessed and utilized in various systems no matter where it was created. With this superpower, you remove any constraints such as the requirement for many different logins to multiple systems.

Once the lock to your data is broken, users can display information inside the applications they use, regardless of where that data was generated or primarily housed. It’s your data and it should be accessible according to your business rules, not villainous vendor license agreements.

This superpower includes multiple options for integrating data between systems, depending on the scenario, and federation data services to Open APIs. Utilizing the right approach to meet specific business requirements is necessary in the age of complex IT infrastructure. These needs range from authoring tools, federating data from various and dissimilar databases, and triggering processes and workflows. Using this superpower will ensure that the right data is available to the right people—making slow, cumbersome business processes move at light speed.

Ability 2: The Trusted Sidekick: Collaborate in Context

Every superhero has one, the trusted sidekick, there at a moment’s notice, when all seems lost, they show up and make the difference between success and failure. In PLM, the sidekick is collaboration in context. Not social collaboration, but collaboration where everyone is on the same page as to the problem to be solved, and it’s documented for all to see, now, and in the future.

Clear and easily available communication results in strong requirements and fast innovation. Using the pervasive tools mentioned earlier, along with email and/or Excel, don’t offer the traceability required for developing, manufacturing, and servicing complex products. Without connecting the context of the discussion thread to a part, requirements, or next generation design ideas, the collaboration thread is broken. Combat this by providing the workforce with a secure, connected, and collaborative environment for promoting efficient product development.

Users throughout the extended enterprise, employing this superpower, can easily view and comment on parts and documents with security, control, and include context to day-to-day product development discussions. Companies report the ability to quickly pivot, achieving faster input across roles, disciplines, and throughout the supply chain, resulting in better products, delivered faster.

Ability 3: X-ray Vision: Interactively see Through the Noise

The digital thread is valuable only if there are intuitive ways to access it, search it, and explore it. But what is the best way? How can I be sure I am looking at the right content for my business case? How do I filter through all the noise and focus in order to solve an issue like a recall, manufacturing defect, or maintenance problem? What you need are superpowers that provide x-ray vision so the problem you are solving for and the context you need is searchable, and navigable, that you can visualize so that product data “jumps off the page.”

Here are two abilities to support x-ray vision:

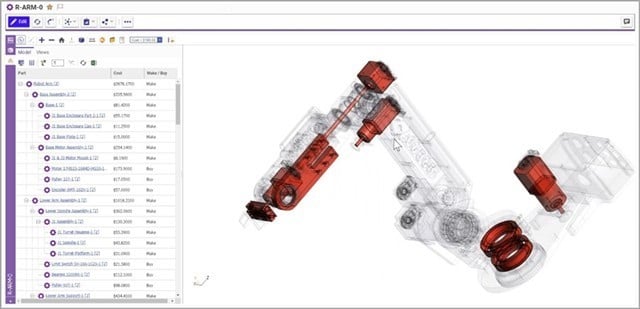

#1 Explore the Digital Thread using 3D models and Tree Grids

Using a 3D model to view the configuration of a product, you can simply select the parts within the product you want more detail on and begin to trace backwards through its history. For example, you could understand what maintenance was performed last week, or who made the decision to select a specific supplier when the product was manufactured 10 years ago.

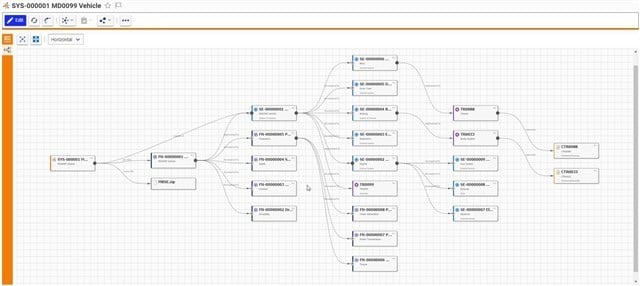

#2 Trace relationships in the Digital Thread with Graph Navigation

Using a graphical representation of the digital thread of a part or a product, users can browse and explore content with context. This view is configurable, based on the user experience required and, better yet, the user can click on what is displayed to interact further with the digital thread to visualize content beyond what has been displayed, to uncover the story to be told.

Ability 4: Control Time: Use the Digital Twin Across the Lifecycle

Ahh, to control time, maybe the greatest superpower of all? But, to create the next level of business value, going backwards or forward through time―content will be king. This requires a superpower that combines a digital twin configuration with the related critical information that has occurred across the lifecycle, enabling traceability across the product lifecycle. Put another way, it's the ENTIRE digital thread, across the lifecycle, from the beginning of time, and all related data collected throughout a product’s life.

This superpower helps your organization gain crucial insights to make informed decisions throughout every aspect of the product lifecycle—improving communication and collaboration and resulting in the creation of better products, with a shorter time to market.

It is this traceability, the ability to go back in time, that creates the superpower. For example, if technicians cannot locate or access information related to parts, job plans, or service bulletins―a.k.a. searching the past―productivity suffers, impacting equipment downtime and workforce productivity.

With context and traceability in place, you can also peer into the future. Using digital twin configurations, in conjunction with predictive analytics tools, allows the outcome to be more accurate, as you are comparing operating data with individual context. You can also simulate what will happen to a product operating now by using its data, in context to the configuration, to predict what will happen if specific scenarios occur.

Conclusion

Using these superpowers contained in the Aras Platform enables the creation and sustainability of the digital thread. This allows organizations to collaborate in context while a product is in development, in manufacturing, or out in operation. But just as important, it captures a historical representation of decisions that have been made by stakeholders that led to the product that is actually operating in the field—the ultimate superpower indeed!

Accessing this information after the fact and visualizing it in intuitive ways, speeds up use cases for failure diagnosis, design questions, and more. Supporting these use cases without a digital thread is time consuming, if not impossible, and creates an unsustainable future for your organization. So, what’s your favorite superpower?